16m² /

French design and production workshop.

Some of our parts are produced in-house. This means that we retain complete control over the manufacturing process, from the choice of materials and manufacturing methods, right through to packaging.

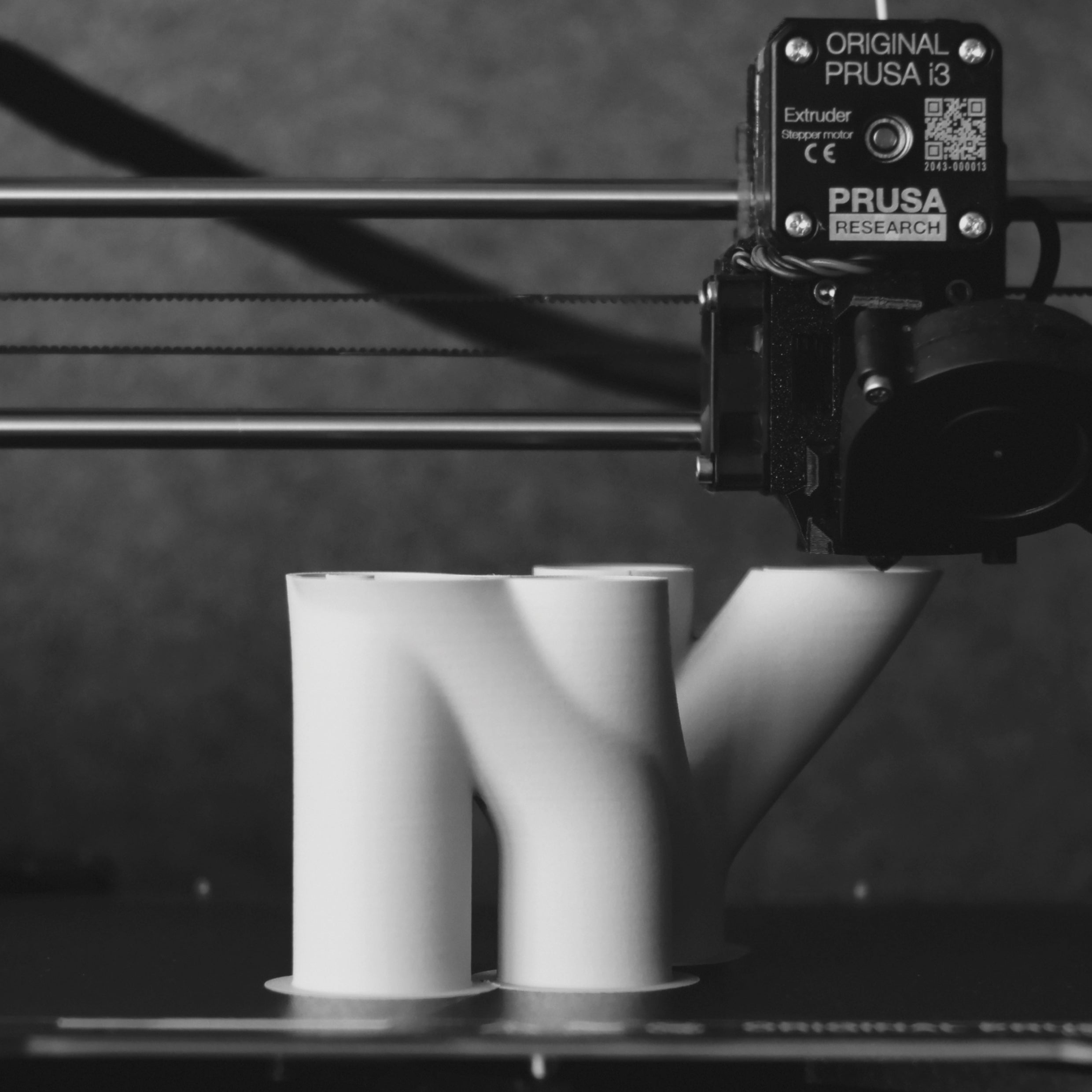

When it comes to manufacturing, we want to keep to processes that require little energy and few resources, but a great deal of knowledge and expertise. Casting and 3d printing are the two main techniques we use. Casting allows us to use healthy, VOC-free, recyclable materials (gypsum powder - water-based resin). Backing molds are made on our premises using 3d printing. 3d printers came to our attention because of their energy advantages (low power consumption), wide choice of materials and ease of installation (unlike heavy industry).